- Heavy duty one-piece base construction of welded carbon steel tubing.

- Vertical upright construction of .250″ wall DOM Steel tubing.

- Patented internal assembly designed for ease of vertical height adjustment.

- All carbon steel components are coated with a rust inhibitive primer and finished with “Steel It” polyurethane paint.

- All aluminum parts are anodized.

- Stands are supported on 4″ diameter locking casters (leveling pads are optional.)

- Each T-base stand is labeled with a warning label that lists weight limitations and safety precautions for operator protection.

T-Base Stand

H-Base Stand

- Heavy duty one-piece base construction of welded carbon steel tubing.

- Vertical upright construction of .250″ wall DOM Steel tubing.

- Patented internal assembly designed for ease of vertical height adjustment.

- Traverse construction of Thomson bearings and rails.

- Traverse assemblies are equipped with a “half nut” feature allowing both “quick positioning” and “fine adjustment.”

- All carbon steel components are coated with a rust inhibitive primer and finished with “Steel It” polyurethane paint.

- All aluminum parts are anodized.

- Stands are supported on 4″ diameter locking casters (leveling pads are optional.)

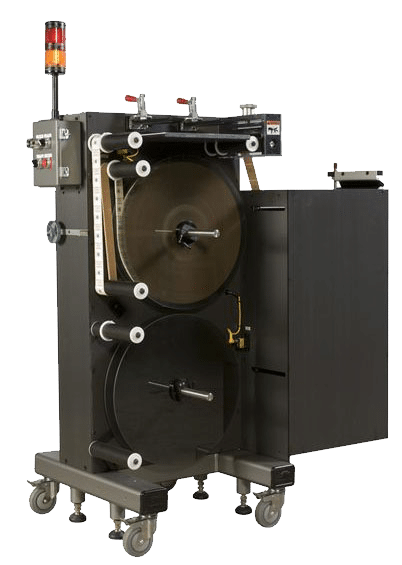

CFUD

The CTM Continuous Feed Dual Unwind (CFUD) is a stand alone unit designed to eliminate down-time associated with supply roll changeover, therefore increases production speeds.

Continuous feed dual unwinds improve efficiency and lost time of any roll-fed labeler by providing nonstop, uninterrupted label supply at high speeds. The continuous feed dual unwind functions as a standard loose loop controlled powered unit. When the supply roll in use unwinds to a predetermined level, a sensor activates a warning light and signals the drive to feed the remaining labels into a holding bin. The second roll of labels is then spliced to the end of the web as the labels in the bin are consumed. The operator completes the changeover by reloading the empty station and resetting the system for the next changeover.

The CFUD is equipped with low label and end of web alarms with a strobe light indicator as standard features. There is a dual manual clamping system on the splicing table. These features maximize use of label material.